- Home

- Machines

- Press Brakes

- MBHSA

- MBHSA-12320

MBHSA-12320

STANDARD EQUIPMENT:

Two axis back gauge

One axis CNC control:X – axis

One axis manual adjustment: R – axis

Precision-made back gauge fingers

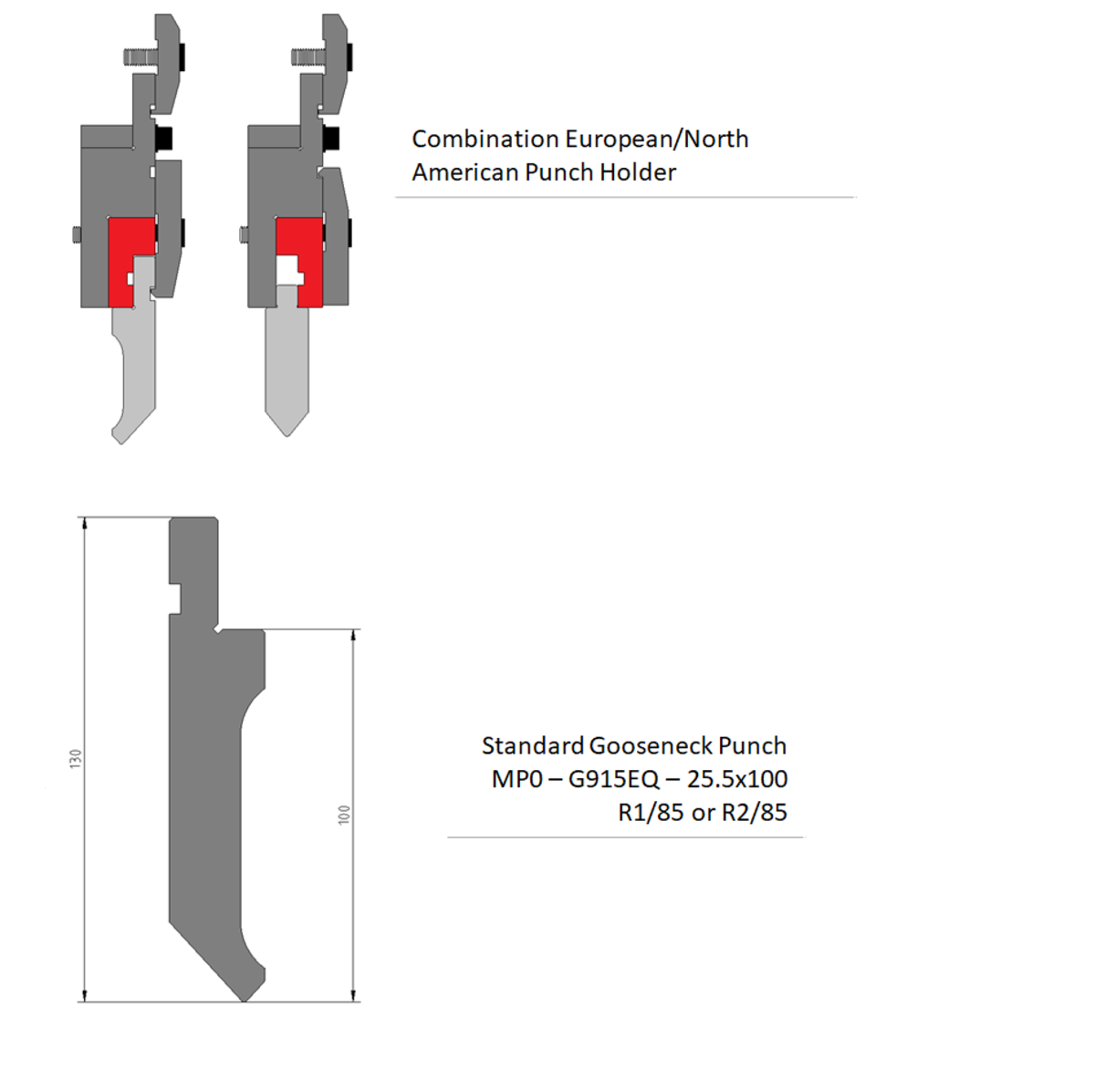

Fully equipped with Masteel tooling and clamping system

Floating-adjustable die clamping system for various die application

Hardened and precision ground tool steel gooseneck punch: 53-58RC;100Ton/M(33Ton/Ft) capacity

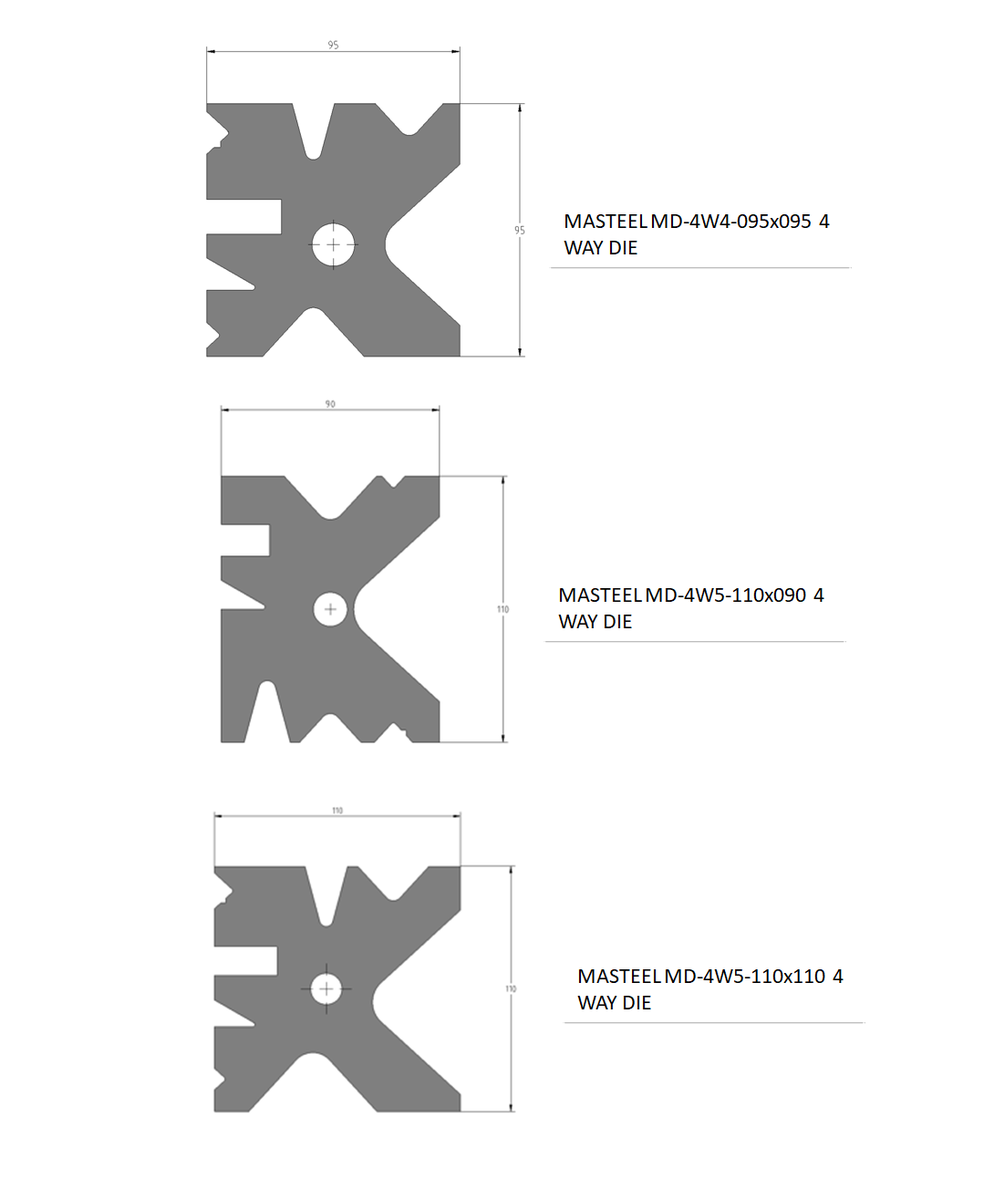

Hardened and precision ground Masteel 8 openings, 4-way die: HB190-260

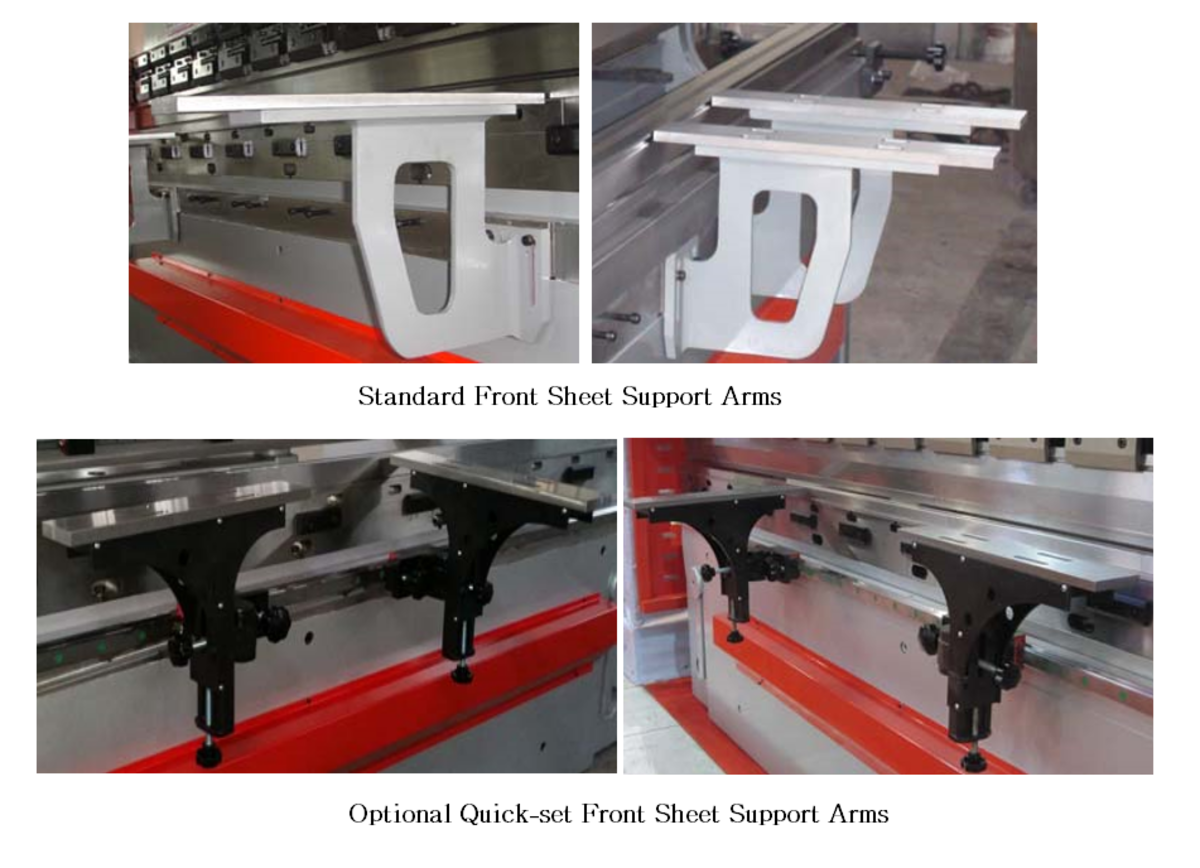

2 - Front support arms

OPTIONAL EQUIPMENT:

CNC R axis , Central lubrication, Safety light curtain

Interlock Back Guard, Quick- set front sheet support (2 SETS)

Special top and bottom tools,

440 or 600V Electrical, Laser protection system for die area

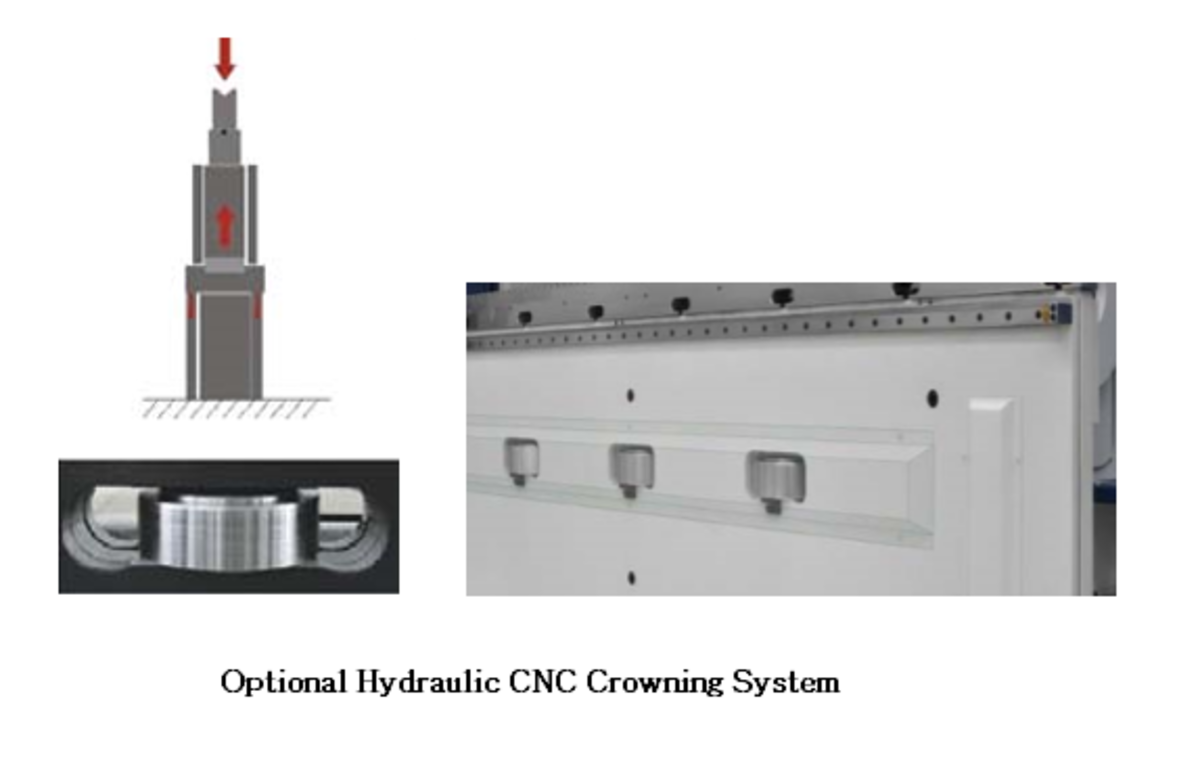

Hydraulic oil coolant, WILA Manuel Anti-Deflection system

Nema 12 Electrical Cabinet w/ Thermal Breaker Disconnect

WILA Hydraulic top and bottom tool holding system

WILA Anti-Deflection System which operates automatically with DNC unit according to tonnage applied

Select Machine Size/Model Here

Specifications

| MODEL | MBHSA-12320 |

| Max. Capacity Tons | 320 |

| Max. Bending Length | 12' |

| Distance between Frames | 122" |

| Height of Bed | 36" |

| Bed Below Floor | __ |

| Depth of Throat | 12 – ¾" |

| Length of Ram Stroke | 10" |

| Fast Approach Speed IPM | 190 |

| Press Speed IPM | 19 |

| Fast Return Speed IPM | 188 |

| Max. Open Height | 20-1/2" |

| Main Motor | 30 |

| Back gauge Travel | 28" |

| Weight Lbs | 36,000 |

| Dimensions L x W x H | 150x 70x110 |

| TOOLING INCLUDED IN PRICE | |

| PUNCH HOLDER | COMBINATION EUROPEAN/NORTH AMERICAN |

| PUNCH | GOOSENECK MP0 – G915EQ -25.5x100 R1/85 OR R2/85 |

| DIE | MASTEEL MD-4W5-110x110 4 WAY DIE |