- Home

- Machines

- L&L CNC LATHES

- CLB-Series

- CLB-3000

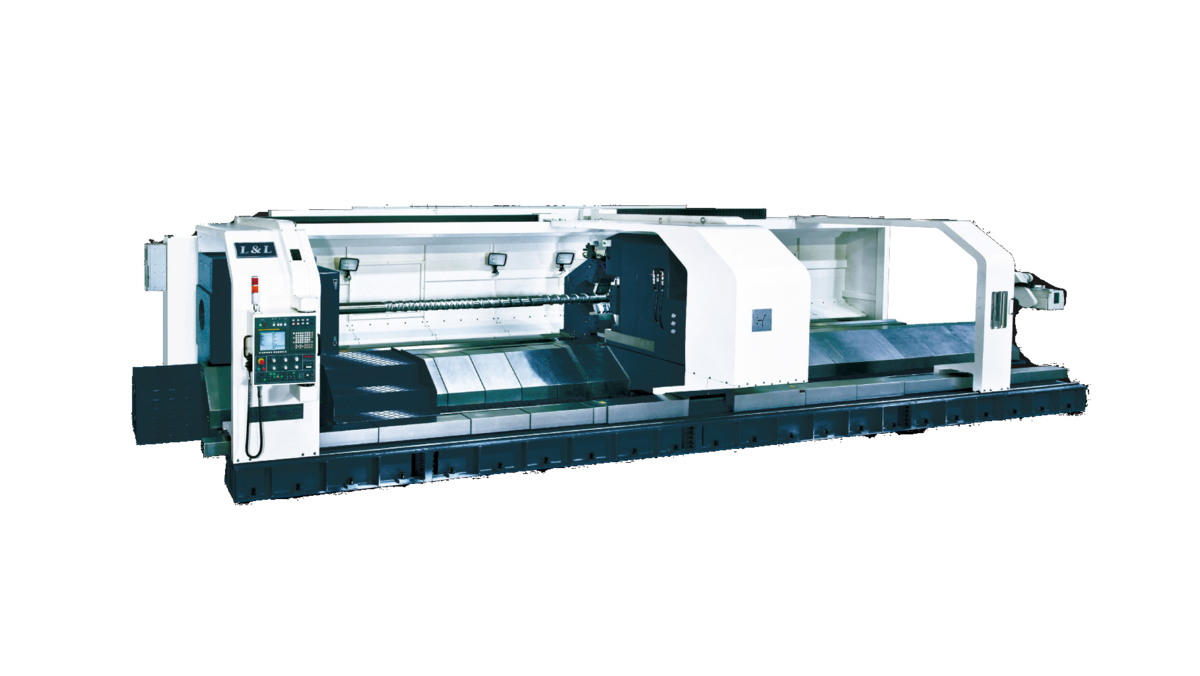

CLB-3000

FEATURES

The common problem for slant bed type turning centers is the interference between the machine bed and the steady rest, which is necessary for turning large diameter and long workpieces.

The CLB-Series eliminates this problem with the revolutionary 5 guideways design.

This design allows tools to cut past the steady rest without interference.

The CLB-Series is designed to perform multi-tasking processes on complex parts that require turning, milling, drilling, tpping, and even boring.

The X, Y, Z, C axes can be controlled simultaneously to support complex parts with a high degree of machining difficulty.

Request Quote on This Model

Select Machine Size/Model Here

Specifications

| Model | CLB-3000 | |||||||||||

| Swing over bed | Ø950 mm | |||||||||||

| Maximum cutting diameter | Ø950 mm | |||||||||||

| Center height | 675 mm | |||||||||||

| Distance between centers | 3000mm | |||||||||||

| Carriage type | Box type | |||||||||||

| Carriage width | 1090 mm | |||||||||||

| Cross slide width | 560 mm | |||||||||||

| Bed width | 990mm(39")+ sub-way | |||||||||||

| Machine length | 9330mm | |||||||||||

| Bed way | 2 box way for carriage 1 V way and 2 flat ways for tailstock and steady rest | |||||||||||

| Controller | FAGOR 8055-TC (std.) | |||||||||||

| Headstock | ||||||||||||

| Spindle bore | Ø153mm (6") | Ø205mm (8") | Ø230mm (9") | Ø255mm (10") | Ø305mm (12") | Ø405mm (16") | ||||||

| Spindle nose | A2-11 | A2-15 | A2-15 | A2-20 | A2-20 | A2-28 | ||||||

| Spindle speed | 9~900rpm | 9~650rpm | 9~650rpm | 7~400rpm | 7~400rpm | 5~250rpm | ||||||

| Spindle center | MT#6 | |||||||||||

| Turret | ||||||||||||

| Turret mode | Sub spindle+20 tools magazine + ATC system | |||||||||||

| Tool shank BT50, CAT50, ISO50 | ||||||||||||

| Spindle motor | 15/22KW 95.5Nm | |||||||||||

| Tool size | 32 mm | |||||||||||

| Tailstock | ||||||||||||

| Quill diameter | Between centers | 3~6M | Ø200mm | |||||||||

| Between centers | 7~16M | Ø250mm | ||||||||||

| Quill stroke | 250mm | |||||||||||

| Tailstock center | MT#6 | |||||||||||

| Body movement | Motorized (motor through rack and pinion) | |||||||||||

| Quill movement | By hydraulic | |||||||||||

| Feed | ||||||||||||

| X-axis rapid traverse | 5000mm/min | |||||||||||

| X-axis ballscrew | Ø50mm*P5 | |||||||||||

| X-axis feed range | 0.1~3000 mm/min | |||||||||||

| X-axis stroke | 550mm | |||||||||||

| X-axis transmitting | Directly by coupling | |||||||||||

| Z-axis rapid traverse | 5000mm/min | |||||||||||

| Z-axis ballscrew | Ø80mm*P10 | |||||||||||

| Z-axis feed range | 0.1~3000 mm/min | |||||||||||

| Z-axis stroke | 3000mm | |||||||||||

| Z-axis transmitting | Ballscrew rotates through 1:4 planetary gear reducer | |||||||||||

| Y-axis rapid traverse | 5000mm/min | |||||||||||

| Y-axis ballscrew | Ø40mm*P5 | |||||||||||

| Y-axis feed range | 0.1~3000 mm/min | |||||||||||

| Y-axis stroke | ±100 mm | |||||||||||

| Y-axis transmitting | Directly by coupling | |||||||||||

| Boring bar compound with tailstock (opt.) | ||||||||||||

| Boring bar diameter | Ø150mm | Ø200mm | Ø250mm | |||||||||

| Internal hole maximum cutting diameter | Ø250mm~Ø840mm | Ø300mm~ Ø890mm | Ø350mm~ Ø940mm | |||||||||

| Internal hole maximum cutting depth | 1500 mm | 2000 mm | 2500 mm | |||||||||

| Feed | ||||||||||||

| X2 rapid traverse | 5000mm/min | |||||||||||

| X2 ballscrew diameter | Ø40mm*P5 | |||||||||||

| X2 feed range | 0.1~3000 mm/min | |||||||||||

| X2 stroke | 300mm | |||||||||||

| X2 transmitting | By ballscrew | |||||||||||

| Z2 rapid traverse | 5000mm/min | |||||||||||

| Z2 ballscrew diameter | Ø63mm*P10 | |||||||||||

| Z2 stroke(when internal hole cutting) | 3000 mm | |||||||||||

| Z2 feed range | 0.1~3000 mm/min | |||||||||||

| Z2 transmitting | Ballscrew rotates through 1:4 planetary gear reducer | |||||||||||

| Standard accessories | ||||||||||||

| Lubrication pump | Spindle | 1/4HP 6.5L/min | ||||||||||

| Carriage | 25W 130cc/min | |||||||||||

| Coolant pump | 15 Bar with oil skimmer | |||||||||||

| Hydraulic pump | 2HP Between centers 3~8M | 5HP Between centers over 8M | ||||||||||

| Chip removal | Front and rear chip conveyor+ front and rear carts | |||||||||||

| Guard | Front two doors + rear splash guard (std.) Fully enclosed guard (opt.) | |||||||||||

| Machine color | Machine body black(RAL9011)+ splash guard and doors white(RAL7047) | |||||||||||

| Optional accessories | ||||||||||||

| C-axis system | ||||||||||||

| Steady rest | ||||||||||||

| Steady rest quill diameter | Ø80 mm | Ø105 mm | ||||||||||

| Steady rest capacity | Ø100~Ø300, Ø300~Ø500, Ø500~Ø750 mm | Ø750~Ø950 mm | ||||||||||

| Note 1. X-axis and Z-axis actual cutting traverse will change when equipped with different turrets. 2. Spindle speed will change according to different motors. 3. Machine length excludes the length of chip conveyor. 4. Distance between centers will change based on installing different types of tailstocks. 5. Z-axis traverse = actual workpiece length | ||||||||||||

Request Quote on This Model