- Home

- Machines

- Boring Mills

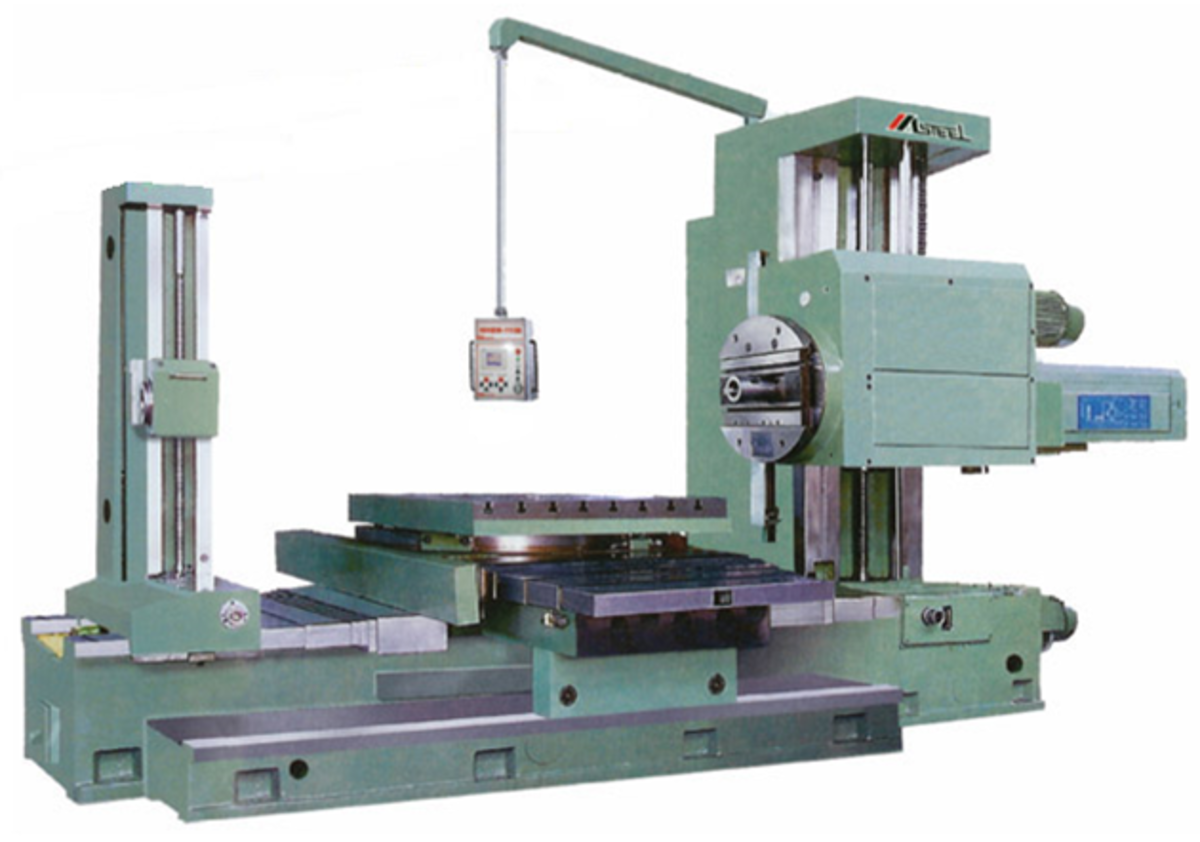

- MAXCUT MHBM-110B CYCLOMATIC BORING MILL

MAXCUT MHBM-110B CYCLOMATIC BORING MILL

Technical Specifications

| Spindle Taper | CAT #50 |

| Boring Spindle Diameter | 4.41” |

| Travel of Boring Spindle | 24” |

| Travel of Facing Spindle | 7.22” |

| Diameter of Facing Plate | 23” |

| Index Rotary Table | 49” x 43.3” |

| Index Rotary Table Load | 6600 lbs |

| Longitudinal Travel | 56” |

| Cross Travel | 64” |

| Spindle to Table | 0 – 48” |

| Programmable Spindle Speed | 8 – 1000 RPM |

| Programmable X Y Z W Axis Feed Rate | 0.040” – 80” / Min. |

| Facing Plate Speed | 4 – 200 RPM |

| Facing Plate U Axis Feed Rate | 0.012” – 60” / Min. |

| X Y Z W Axis Rapid Travel | 80” /Min. |

| Digital Readout Resolution | 0.0005” |

| Main Motor | 20 HP |

| Dimensions: L x W x H | 197” x 115” x 108” |

| Weight | 39600 lbs |

STANDARD FEATURES AND EQUIPMENT

|

11” Touch Panel |

Point to point position

control on X Y W axis at accuracy of ± 0.001” |

||

|

Automatic

Hole-Cycle Control Features Automatically calculate hole

position or input hole position directly “GO TO” position control for

rapid approach to hole position Drilling cycle with programmable

feed speed and rapid retract speed Peck dril cycle for deep

hole drilling Floating tapping cycle with

feed rate calculated from spindle speed and TPI |

|||

|

Portable hand wheel unit

with X Y Z W B – 5axis selectionand spindle jogging for easy setup |

|||

|

4 axis DRO – X Y Z and W at

resolution of 0.0005” |

|||

|

Position readout provides

full sceen display on X Y Z W and B axis for better visibility |

|||

|

Programmable feed rate in

inch per minute and calculated feed raate at inch per revolution for cutting

referance |

|||

|

Three feed functions: Rapid

traverse / cutting feed / hand wheel micro adjustment. |

|||

|

Programable spindle / facing

plate speed and automatic shift of high / low gear |

|||

|

Central operating console

eliminates most of the operation handling on the headstock |

|||

|

Automatic hydraulic clamping

/ unclamping coordinate with the feed select on X Y Z W B and U axis clutch |

|||

|

Automatic lubrication |

Power draw bar |

Optional tailstock |

|

|

Optional point to point

position control and DRO on B axis |

|||